1.800.833.7958

► Español

► 中文

Geotech History and Milestones

At Geotech, our mission has always been to contribute to environmental progress by manufacturing scientific field equipment. We are proud of our reputation for producing high quality and reliable products that aid in the monitoring of global environmental conditions. As environmental issues continue to evolve, we make it a priority to Invite Innovation and improve upon our existing designs in order to provide the most effective solutions for environmental professionals. We are committed to being a model environmental equipment manufacturer and will continue striving for excellence in the years to come.

-

Humble Beginnings

1956

Leonard Mold and Die was founded in Denver in 1956, a small business originally specializing in toolmaking and machining. Thanks to its history of innovation and commitment to quality, Geotech quickly became a respected name in manufacturing. Today, Geotech is a leading manufacturer of environmental equipment for a variety of industries. However, the company has never forgotten its roots.

-

1978

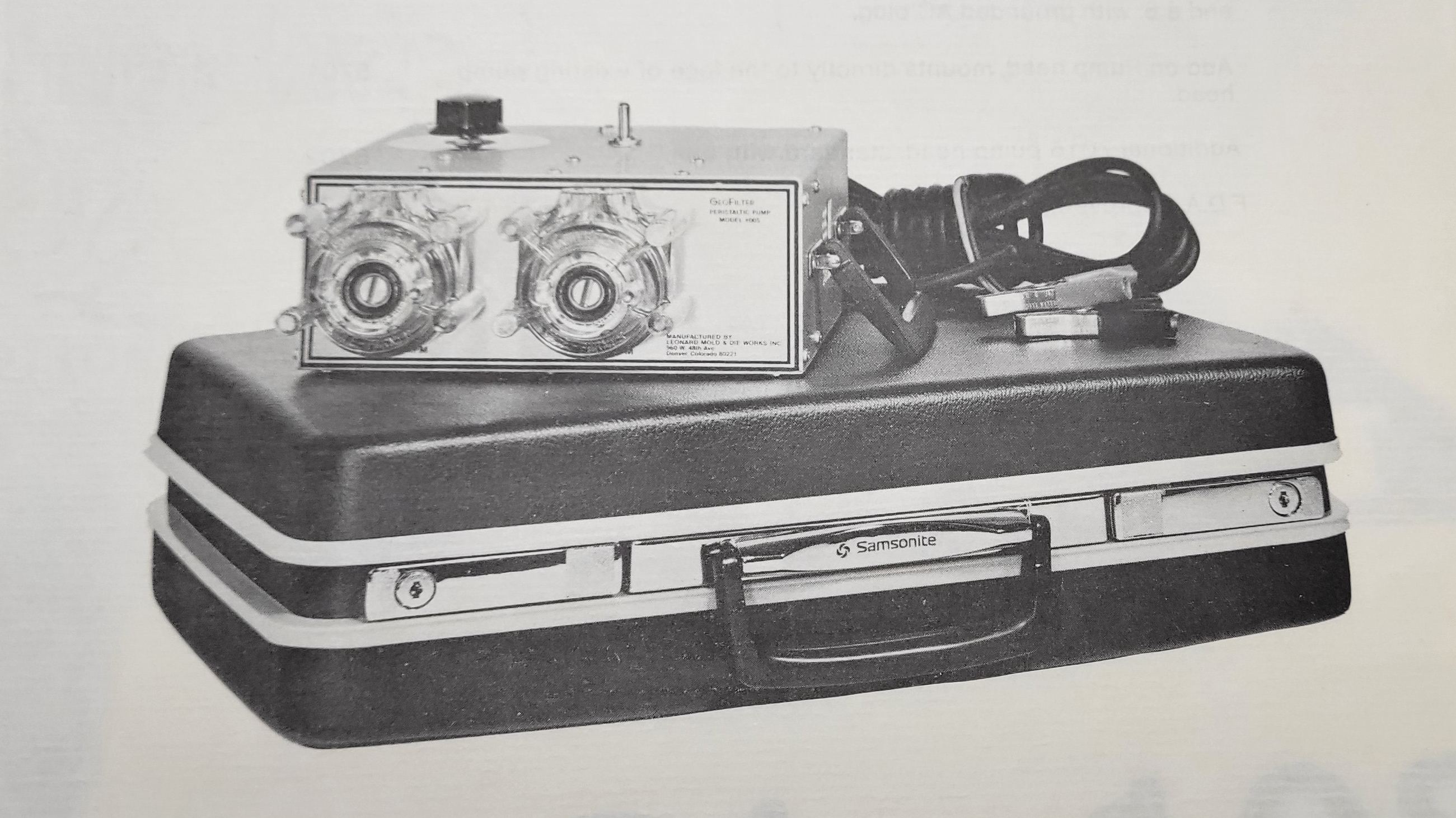

Partnering with USGS

Geotech founder, Jerry Popiel, developed the Geopump Peristaltic Pump with the U.S. Geological Survey for the purpose of collecting shallow groundwater and surface water samples to comply with EPA Clean Water Act of 1972 initiatives. As a result of the partnership, Geotech's equipment became industry standard. Geotech's pumps are now used by environmental professionals around the world to collect water samples for analysis.

-

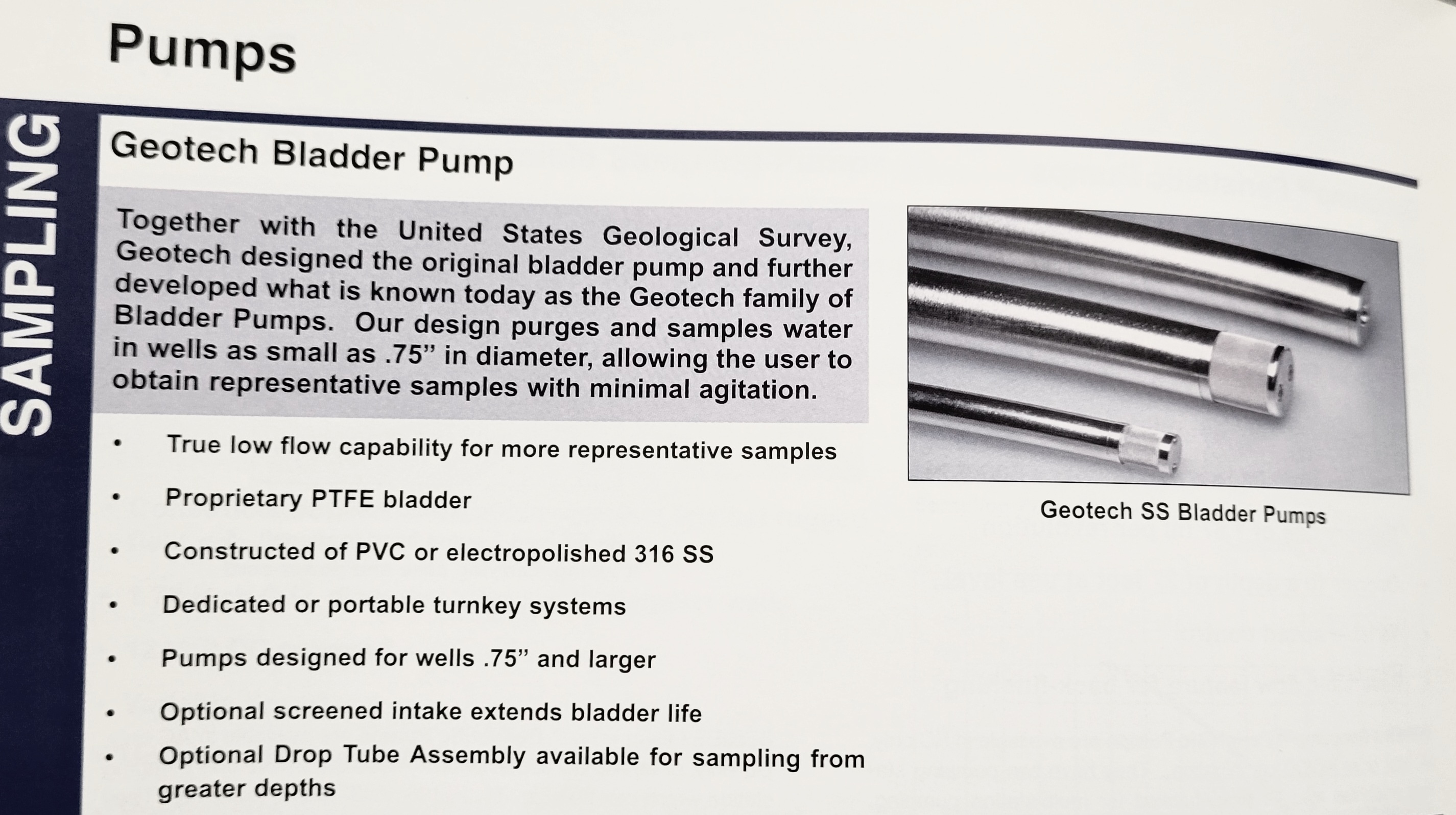

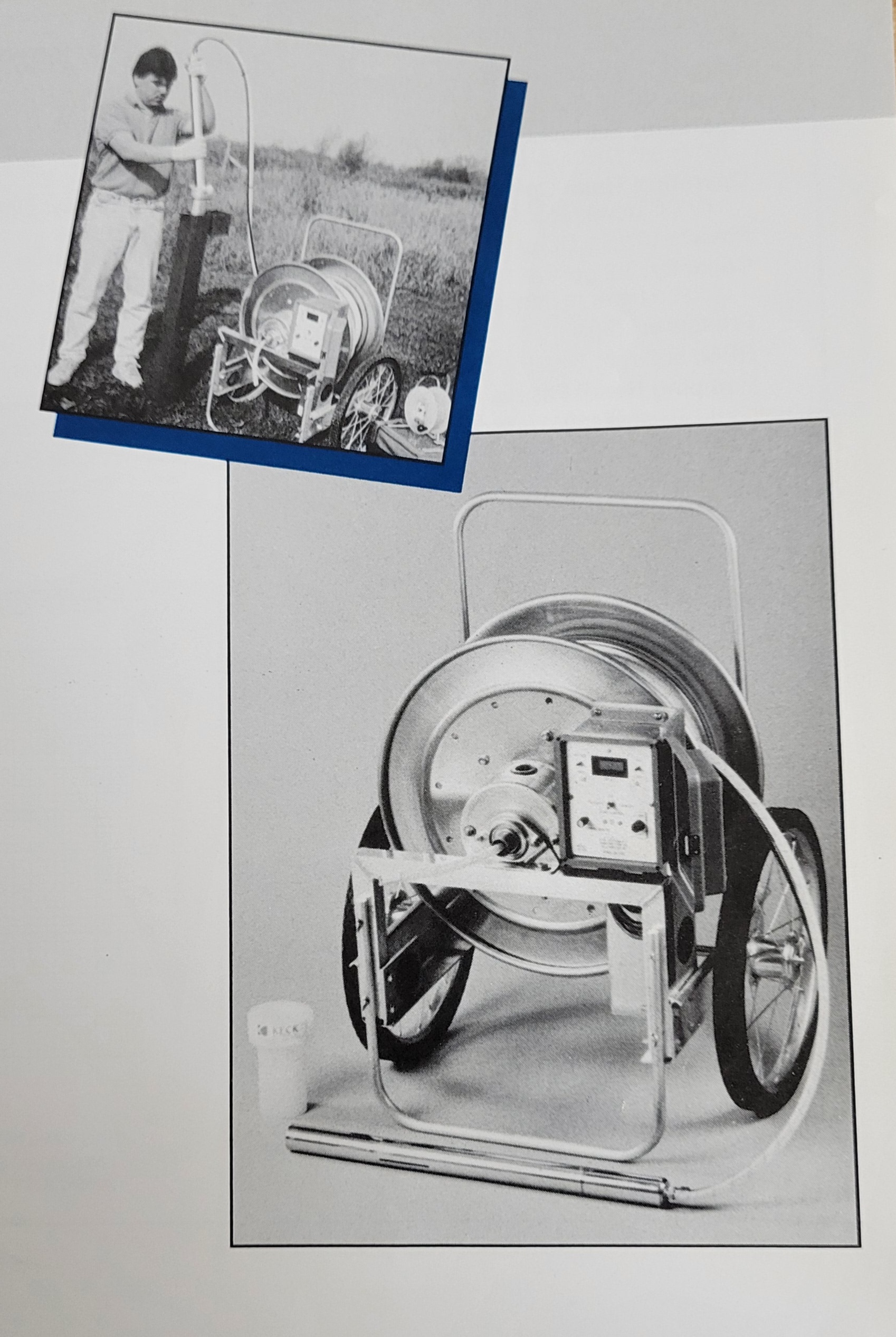

The Bladder Pump System

1996

In response to new EPA regulations, Geotech announced the launch of its new bladder pump system. This system represented a major development for wastewater management. The EPA introduced low flow purging and sampling methodology, and with its intuitive design and user-friendly interface, the bladder pump system was easy to operate and maintain. Wastewater management is now easier and more efficient than ever before.

-

1997

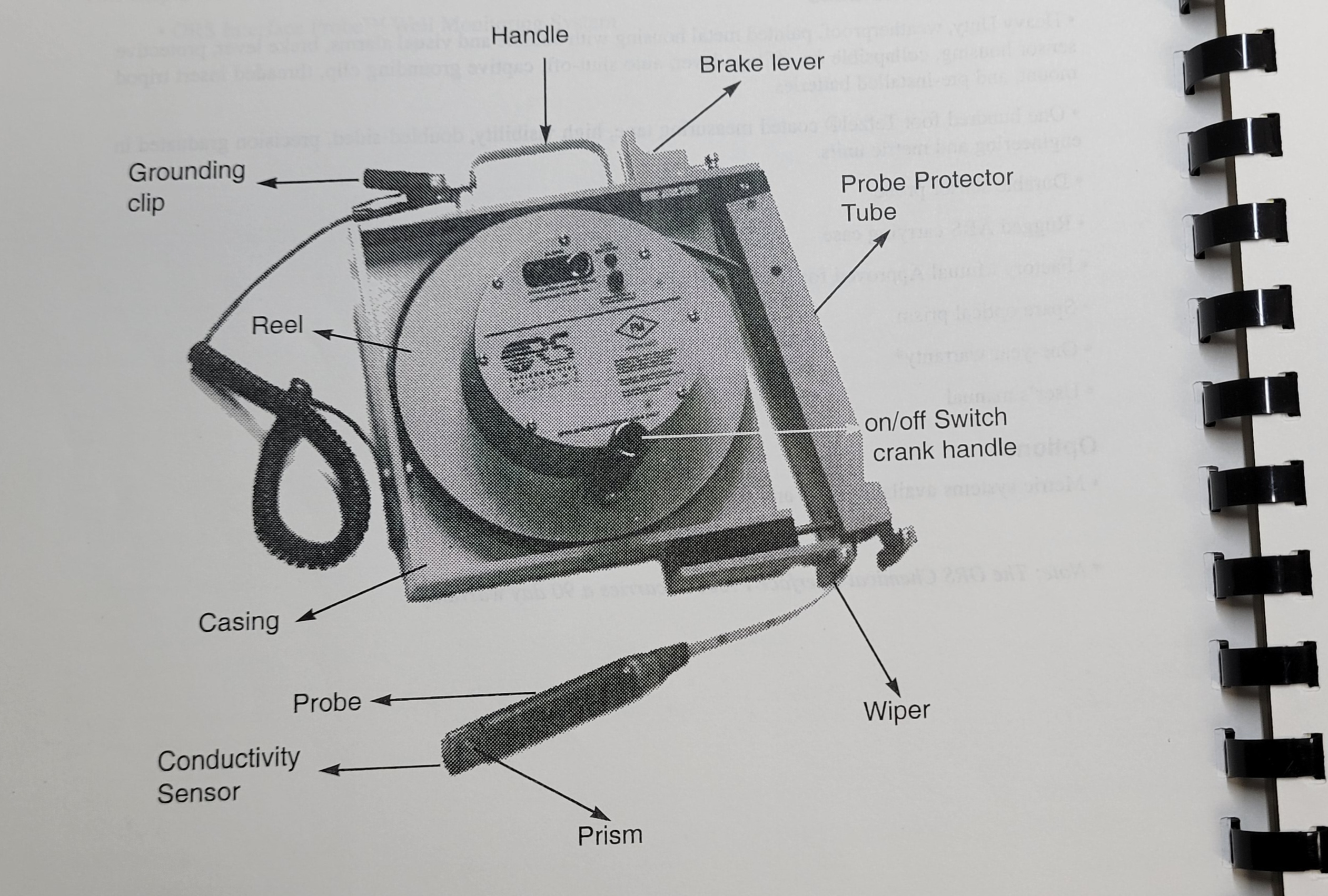

ORS

Geotech's acquisition of ORS, Inc. in 1997 was a watershed moment for the company. Not only did it broaden Geotech's influence into active product recovery and interface meters, but it also allowed Geotech to tap into a new market in New Hampshire and continue its growth trajectory. The move came at a time when hydrocarbon contamination concerns were leading regulatory clean-up efforts, and the ORS product line gave Geotech the ability to provide much needed equipment for clients.

-

Keck Instruments

1999

In 1999, Geotech announced the acquisition of Keck Instruments. The new pneumatic hydrocarbon recovery systems and interface meters were designed to provide superior performance and reliability. The acquisition resulted in the launch of the Lansing, Michigan office location and further advancements in remediation technology.

-

2005

Marschalk

Geotech acquires Marschalk Corporation, representing a major milestone for the company and its water quality equipment production. This acquisition enhanced Geotech's bladder pump technology offerings and helped to launch its Raleigh, NC office location. The location provides Geotech with a new base of operations in the Southeast region of the United States. With new access to a large potential customer base, the company can now better serve its existing customers in the region.

-

Headquarters gets an Upgrade

2006

Denver has been the home of Geotech since the company was founded in 1978. The city has seen the company grow from a small machine shop to a leading manufacturer of environmental equipment. In 2006, Geotech moved to its current 125,000 square-foot manufacturing plant and headquarters in Denver.

-

2011

International Expansion

Geotech broke ground on its first international office location in Beijing, China in 2011. The new location improved Geotech's international relations and export channels to global customers and distributors. This same year Geotech acquired Bisco which strengthened Geotech's position in the market and allowed the company to set up shop in southern California. Geotech's expansion into Beijing and California was a key moment in the company's history, providing Geotech with a strong foothold in the global market.

-

Improving Worker Safety

2012

Worker safety has always been a priority within Geotech. In cooperation with Arcadis, the company manufactured the ZipLiner, a cutting-edge device designed to improve worker safety conditions when opening traditional liners. By making worker safety a priority, Geotech helps to create a safer, more efficient field sampling process for our clients. The ZipLiner is just one example of how Geotech constantly innovates to improve worker safety. Geotech continues exploring new technologies and ideas to make sure that our workers can do their jobs safely and efficiently.

-

2013

INW

Geotech acquired a portion of INW (Instrumentation Northwest), which enhances electric submersible pump configurations and resulted in the launch of the Kirkland WA and Sacramento CA office locations. The acquisition of INW allows Geotech to expand its product offerings and continue to provide the highest level of customer service.

-

Meeting New Standards

2013

Geotech began certifying ISO 9001:2008 back in 2013, affirming our commitment to quality management principles that assure a customer-focused approach to design, development, production, and sales and service. This was an important milestone for Geotech, and we continue to update this certification to this day.

-

2015

Aqua VISION

Geotech announced the acquisition of Aqua VISION. This move resulted in the commercialization of the Colloidal Borescope, a groundbreaking tool for characterizing groundwater flow direction and velocity in situ. Geotech is now positioned to provide our customers with the most advanced tools for groundwater flow.

-

To the Skies

2015

Geotech introduces unmanned aircraft or drones with the acquisition of Leptron Industrial Robotic Helicopters, Inc - an innovative technology being introduced to environmental remote sensing and aerial surveying. The addition of Leptron's innovative technology provides Geotech customers with a new tool for environmental research and assessment. The use of drones has already revolutionized many industries, and it is clear that the potential applications for this technology are virtually limitless. Geotech is committed to providing its customers with the most advanced solutions available, and the acquisition of Leptron is yet another example of this commitment.

-

2017

Geotechnical

Geotechnical Services join the Geotech regional service center team in Orange CA in a partnership to better serve Geotech and Geotechnical Services customers nationwide. Today, the regional service center team provides an invaluable resource for Geotech customers across the country.

-

Extrusion

2018

Geotech acquires Hi-Tec plastics of Denver to expand plastic extrusion manufacturing capacity while continuing to make OEM parts. The acquisition helped Geotech to expand its plastic extrusion manufacturing capacity and continue to provide high-quality products to its customers.

-

2019

Improving Weather Forecasting

In 2019 we announced our contract manufacturing agreement with Anemoment to produce and distribute the world's smallest and lightest 3D ultrasonic wind and weather sensor. The sensor goes on to be used in a variety of applications, including consumer electronics, automated weather stations, and drones.

-

Water Sampling Revolution

2021

Innovation is key to protecting our environment and combating the continuous increase in toxins. That's why we chose to partner with Thyng Environmental Industries, LLC to manufacture and distribute their patented FieldSink Environmental Station. Providing a cleaner and quicker solution to water sampling in the field not only improves the experience for the environmentalist, but also provides less contaminated samples which improves the industry as a whole.